Our goal at Lend-An-Arm is to eliminate waste, utilize technology, and support our customers. To that end we present a production philosophy that mimics the “plug and play” concept of a simple USB Stick. If your production process has a big expensive machine that produces multiple different products with post production process steps, then you should take a look at this production philosophy. if you have a graveyard of machines taking up valuable production floor space that preform similar tasks , then you should take a look at this production philosophy. It is a simple approach that requires just a little standardization of two major components the Frame and the Cassette to generate a huge cost savings that can be realized over a short period of time.

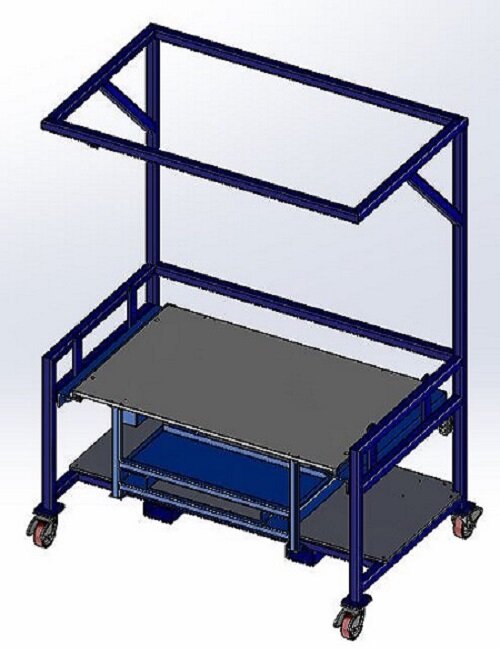

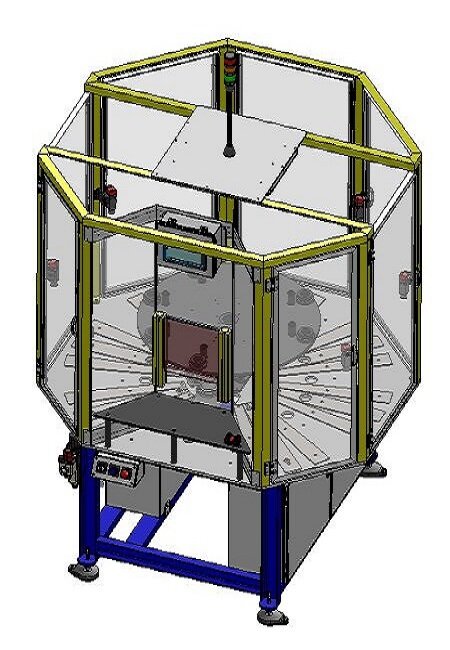

THE FRAME

First we create a frame that can house 80% of your products for a particular production process. Sometimes this requires a Small, Medium, and Large frame other times we can get away with one size fits all. Next we pick what controls platform your team or Lend-An-Arm can support with minimal cross training and development effort. Finally we generate an interface that accommodates your factories requirements and the cassette interface. Here are some examples:

Basic Frame

Dial Assembly Cell

Large Basic Frame

Collaborative Robot Frame

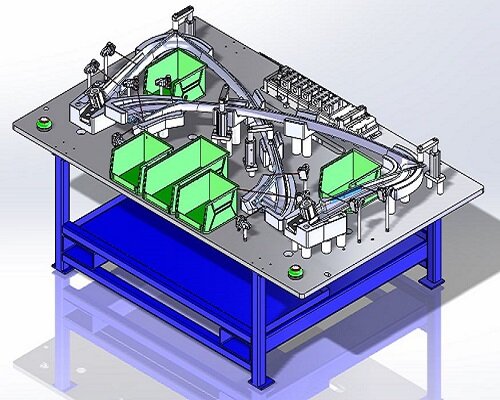

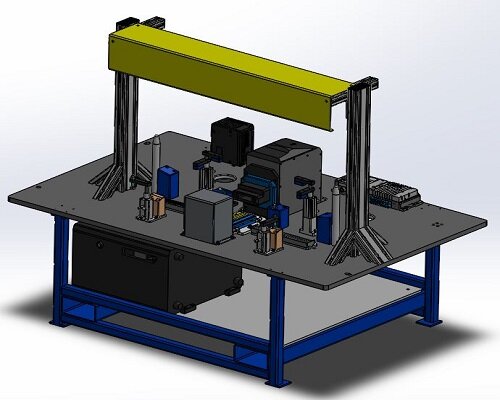

THE CASSETTE

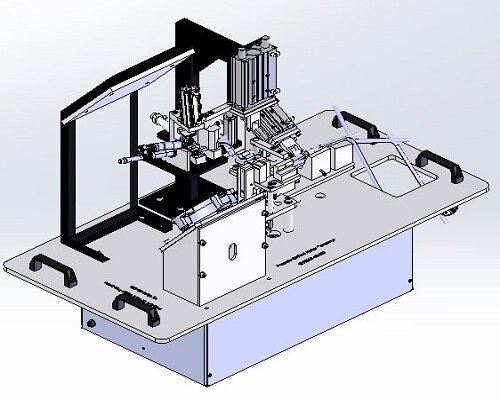

The cassette houses the product specific tooling, sensors, and equipment necessary to accomplish the post production process steps. The cassette is built on a simple and easy to manufacture structure. This structure needs to quickly and safety interface with THE FRAME and allow for self supported storage on a vertical rack. Finally is the cassette to frame interface can be as simply as power, Ethernet, and air or as dynamic as a multi-pin conductor for Inputs and Outputs. Here are some examples:

Basic Frame

Dial Assembly Cell

Large Basic Frame

Collaborative Robot Frame

THE TRANSFER CART

When a new product is introduced to a production line either maintenance or the operator utilize the transfer cart to remove the cassette from the frame. The this transfer cart can be similar to a pallet jack or even a Automated Guided Vehicle (AGV). Once the cassette is removed it is taken to the inspection station. The authorized personnel hooks the cassette up to the inspection station and a diagnostic is ran on the cassette. If a log of multiple faults, malfunctions, or a preventative maintenance date is met the cassette is flagged for service and taken to maintenance other wise it is stored on the rack.

This manufacturing philosophy is efficient, cost effective, and as simple as the concept of the USB. Today you can run an entire operating system off a USB, store a terabyte of data or, even use it to open a beverage bottle. IF you think this approach may work in your production environment let us know and we would love to discuss the possibilities.